With a rich experience of over three decades, Awanti Polymoulds, a Blow Mould Manufacturer in India has been providing high-quality PET blow moulds to the beverage industry. Precision machining is key to manufacturing accurate, durable, and high-quality moulds.

What is precision machining?

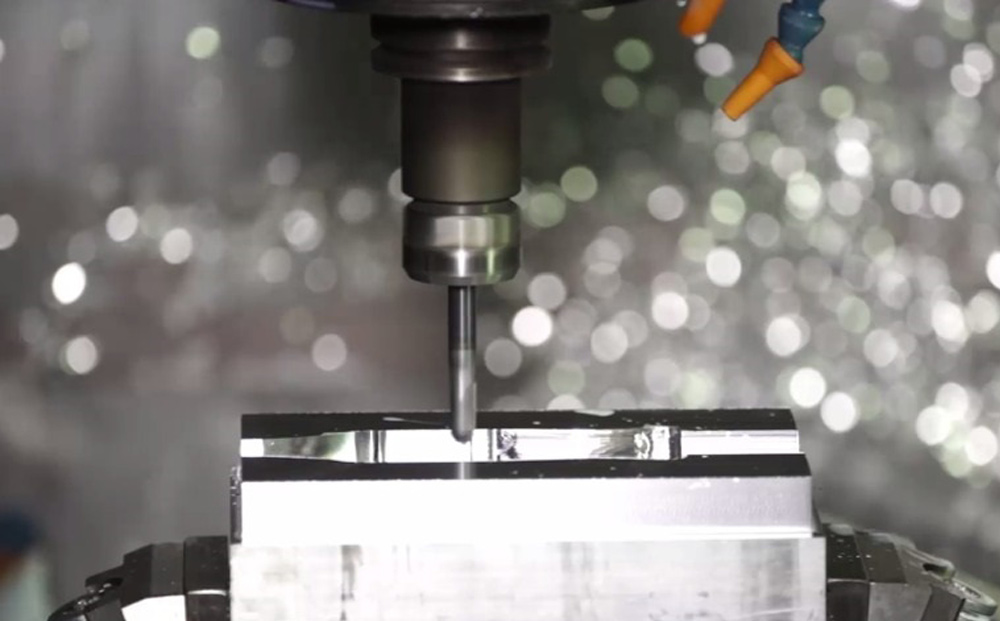

Precision machining is a process that removes excess raw material from a block or workpiece, while holding close tolerance finishes, to create a finished product. Simply put, it means shaping large pieces of material into more precise parts, so that they can meet the desired specifications. The methodologies by which this is done are different; the most common ones include milling, turning, and drilling. Precision machining perfectly combines computer-controlled design and human-engineered design.

Advantages of Precision machining-

Reduced production time

Precision machines can work for longer hours without taking a break, automatically and with no human intervention. This leads to great speed and contributes to a faster level of production.

Operational Effectiveness

Precision machinery uses equipment that handles computer animation to handle the initial design. This leads to operational effectiveness and with the combined help of the human workforce and machinery, it leads to higher efficiency and lower production time.

Cost-effective production

One of the biggest advantages of precision machinery is that it has a comprehensive nature in the working process. It automatically leads to a reduction of wastage material, and minimal chances of human errors. In totality, it leads to low production costs.

Consistency in quality

Creating hundreds of tools with the same level of precision and accuracy is a challenging task. The consistency has to be maintained, no matter what. This is possible only with precision machining. This is a win-win situation as having consistent quality not only boosts the company’s brand image but also leads to consistent quality, desired repeatability, and lower rejection at the customer end.

Applications of Precision Machinery

Precision machine tools are used in a wide variety of industries like automotive, electronics, aviation defence, and food & beverage production. Several small and large, simple and complex objects which we use in our daily life, right from toothbrushes to chairs to bottles to automobile parts to electronic parts are produced on precision tools (also called moulds).

Metal Removal Industries

In the metal removal industries, precision machinery technology removes the excess metal from the raw material, thus creating an end product.

Making of musical instruments

Any kind of musical instrument needs to be perfect to hit the right musical notes. Precision machinery is just the right source of making musical instruments without compromising on quality.

Electronic Products

Several electronic products are made of motherboards and various tiny parts. They need to fit well with each other for their optimum use. Precision machining of tools fits the bill in this case.

At AwantiPolymoulds, our strength lies in our highly skilled workforce with an in-depth knowledge of bottle design, mould design, and precision machining. Equipped with world-class Japanese CNC machines, Awanti’s tool room has been manufacturing many PET Blow Moulds year after year, which has resulted into hundreds of delighted customers across 15 countries worldwide. With a visionary approach and effective leadership, we aim at becoming the Best Mould Manufacturing Company in Asia.

Comments

Post a Comment