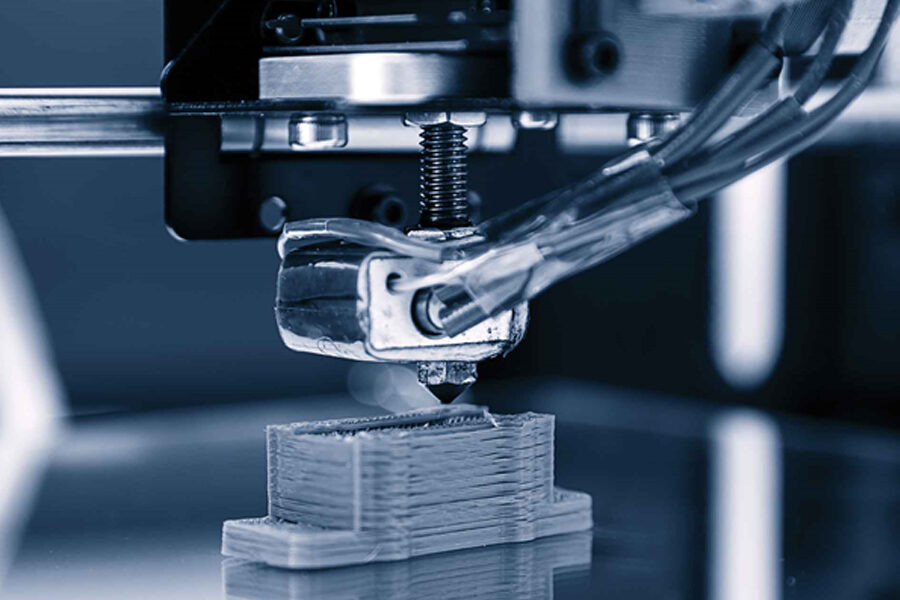

Far from being a process or just a trend, additive manufacturing is more of a technological revolution that comes under the fourth industrial revolution. As the name suggests, the additive manufacturing process works by adding materials. Layers upon layers of materials are deposited successively on top of each other until the desired object is produced.

What is additive manufacturing?

Additive manufacturing (AM) is the industrial manufacturing process that uses computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, to create desired geometric shapes.

How does additive manufacturing work?

The very first step in additive manufacturing is to create a 3D model of the object. This model can be designed using computer-aided design (CAD) software. This CAD file is now converted to a standard additive manufacturing file format, which is usually an STL file. The STL file is then digitally sliced into different layers. The third stage requires the transfer of the STL file and also the setting up of the machine. In the fourth step, the machine that is controlled by a computer builds the model layer by layer. The thickness of the layer dictates the final quality and it depends on the process and machine.

What are the types of additive manufacturing?

There are different additive manufacturing processes with their own set of standards, which include:

1) Binder Jetting

The binder jetting technique of AM uses a 3D printing style head moving around the x, y, and z axes to build up alternate layers of powdered material and a liquid binder used as an adhesive.

The binder jetting technique of AM uses a 3D printing style head moving around the x, y, and z axes to build up alternate layers of powdered material and a liquid binder used as an adhesive.

2) Directed Energy Deposition

Direct energy deposition additive manufacturing is used with different materials like polymers, ceramics, and metals. An electric arc, a laser or an electron beam gun that is mounted on an arm moves horizontally, making filament feedstock, powder, or melting wires to accumulate material with the bed moving vertically.

3) Material Extrusion

In the material extrusion process, spooled polymers either drawn through a heated nozzle or extruded are mounted on a movable arm which builds up melted material layer upon layer with the nozzle moving horizontally and the bed moving vertically.

4) Powder Bed Fusion

The powder bed fusion process encompasses a variety of AM techniques like direct metal laser melting (DMLM), electron beam melting (EBM), direct metal laser sintering (DMLS), selective heat sintering (SHS), and selective laser sintering (SLS). In this process, electron beams, thermal print heads, or lasers are used to melt fine layers of material, and after that, the excess powder is blown away.

5) Sheet Lamination</h4

The sheet lamination process of AM can be split into two technologies: ultrasonic additive manufacturing (UAM) and laminated object manufacturing (LOM). UAM uses an ultrasonic welding method to join thin metal sheets at low energy and low temperature. While laminated object manufacturing is best for creating items with visual appeal and makes use of alternate layers of paper and adhesive.

6) Vat Polymerisation

The vat polymerisation process uses a vat of liquid resin to produce an object layer upon layer. Ultraviolet light is directed through mirrors to cure the layers of resin by photo polymerisation.

7) Wire Arc Additive Manufacturing

In wire arc additive manufacturing, manipulators and arc welding power sources are used to build desired 3D shapes through arc deposition. This process typically uses wire as a material source and takes a predetermined path to get the desired shape.

What are the materials used in additive manufacturing?

There are three types of materials that can be used in additive manufacturing: polymers, ceramics, and metals.

- Polymers: Polymers remain the most popular class of additive manufacturing materials. Acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and polycarbonate (PC) each one offer specific advantages in varied applications.

- Ceramics: Different types of ceramics have also been used in additive manufacturing, including tricalcium phosphate, alumina, and zirconia. Also, alternate layers of adhesive and powdered glass are baked together to produce entirely new classes of glass products.

- Metals: Different metals or metal alloys are used in additive manufacturing, from expensive metals like silver and gold to strategic metals like titanium and stainless steel.

What are the advantages of additive manufacturing?

Additive manufacturing has the following advantages:

- Compared to conventional techniques that have geometric limitations, additive manufacturing can create models swiftly, in hours.

- Additive manufacturing technology allows models to be printed in a single process, and organic shapes can be easily produced. Conventional manufacturing constraints are eliminated or reduced.

- There are fewer resources for machines and fewer skilled labour requirements as compared to conventional model manufacturing.

- Efficient use of material because of the exact production of parts, and there is no overproduction based on any estimated demand.

- Commercial advantage and higher competitiveness, in the form of reduced risk and costs, as the manufacturing time from concept to production, is reduced.

What are the applications of additive manufacturing?

The fields of application for additive manufacturing are diverse. We focus here on industrial usage of additive manufacturing:

- Aerospace Industry

- Automotive Industry

- Food Industry

- Machinery (e.g., turbines)

- Medical (dental, orthopedic)

- Handling and robotics

- Lifestyle and Sports (e.g., jewellery, biking)

- Custom Parts (e.g., surgical tools and automobile parts)

Awanti Polymoulds, a manufacturer and exporter and also the leading blow mould manufacturer in India makes use of additive manufacturing in 3D printing of bottle concepts. We provide advanced solutions for bottle design and mould manufacturing. We specialize in PET Blow Moulds. Awanti Polymoulds is best known for its commitment to quality products and customer satisfaction.

Comments

Post a Comment